Australian Cornish Mining Sites: Burra

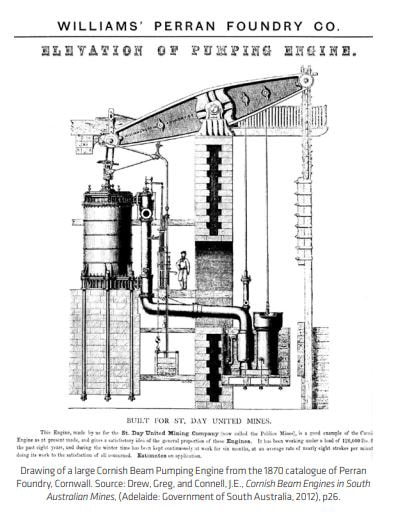

Cornish Technology – Beam Pumping Engines

The Australian Cornish Mining Site at Burra played a major role in the history of Australian mining. The site demonstrates the application of Cornish technology to the extraction and treatment of copper in Australia, and the development of adjacent settlements with their distinctively Cornish cultural traditions.

Burra was a "wet" mine, similar to the Cornish mines. In 1847, the first horse-whims were erected at the Mine to not only raise ore but also water in an effort to keep water down. However as greater depths were reached, it soon became necessary to purchase steam powered pumping engines to dewater the mines.

There were two types of Cornish engines erected at the Burra Burra Mine: the Beam Pumping Engine and the Beam Rotative Engine.

Cornish Beam Pumping Engine in Burra

There were three Cornish Beam Pumping Engines erected in Burra. The first was erected in 1849. It was known as Roachs Engine and was a 50-inch engine. It operated from 1849-1852. It took 40 bullocks, a return trip of two months to haul the engine from Port Adelaide to Burra. The transportation of this engine and the latter two engines rank amongst the greatest achievements in early land transport.

The second Cornish Beam Pumping Engine was known as Schneiders Engine and was an 80-inch engine. The Schneiders Engine operated from 1855 to 1862, although it was installed in 1852. Its commissioning was delayed by the Victorian Gold Rush which had forced the closure of the Burra Burra Mine from 1852 to 1855.

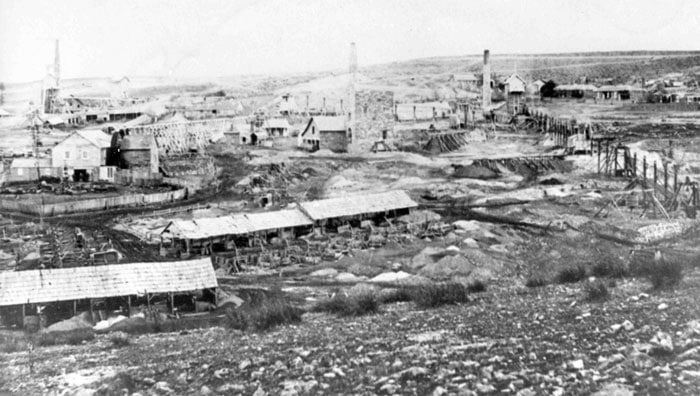

This panorama of the Burra Mine taken in about 1863, is one of the few images of Schneiders Engine-house at the centre of the picture. It is shown here without its shears and roof and its engine removed. Alongside is its boiler-house and on the skyline behind is its flue. In the background on the far left are Morphett's Engine-houses and to the right is Peacocks Winding Engine-house with a row of poles carrying the hauling cable to two shafts at the far right-hand side of the picture.

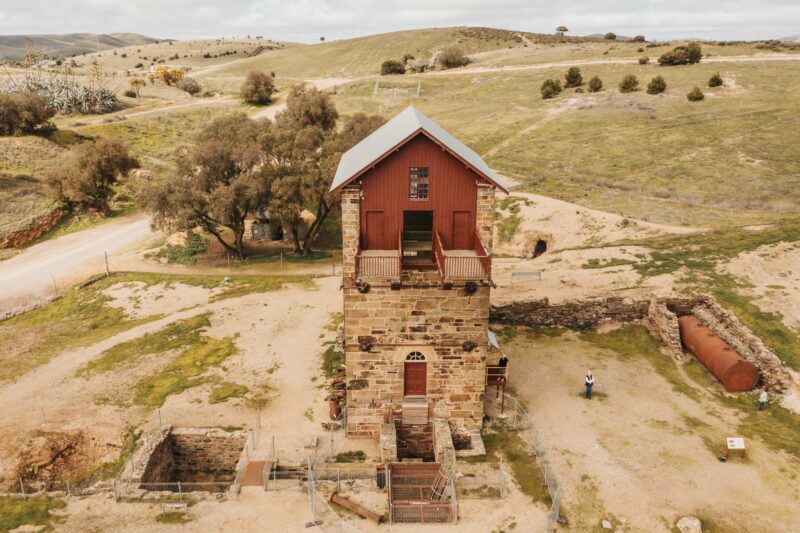

The third Cornish Beam Pumping Engine was Morphetts Engine. Morphetts Pumping Engine House which housed the Cornish beam pumping engine is an extant. In October 1858, the engine house and boiler house was erected and by March 1860, the engine was operational. Working at eight strokes per minute, the engine pumped more than two million gallons of water per day, considerably more than Schneiders Engine, and kept the water in fork at the 60 fathom level.It was in operation until 1877.

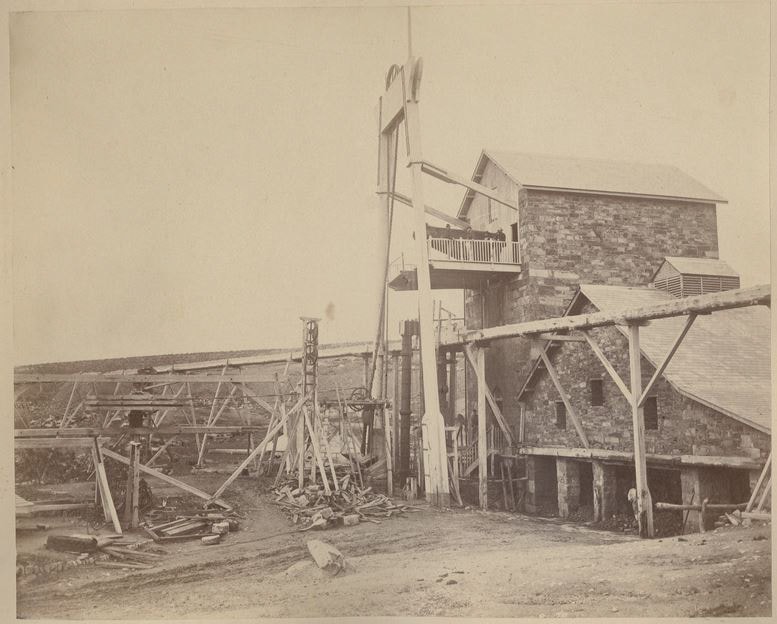

This photograph shows Morphetts Engine House when operating. The horse whim was used to haul rock-filled kibbles to the surface. Between the two shear legs, the rising main (water pipe) discharged mine water into a wooden trough, known as a lauder. The lauder carried the water to the ore dressing tower to be stored in Morphetts pool. A sluice gate allowed water to run from the pool during the day, powering several waterwheels on its way to the dressing floors. The boiler house contained six Cornish boilers-four supplied steam to Morphetts pumping engine and two for the winding engine.

Morphetts Windinghouse

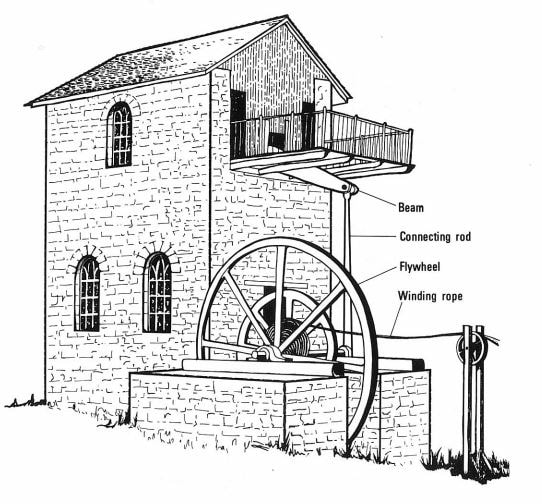

This engine house contained a 20 inch diameter Cornish winding engine (or fire rim) and was erected in 1861. The winding engine was a small version of the pumping engine but given rotary movement by the long rod connecting the nose of the beam to a a crank which turned the winding drum.

Thick flat rope was wound on a drum against the large fly wheel. Between the drum and the hauling shaft the rope was supported on a series of pulleys mounted on wooden posts.

In the1870's, the engine was used to power machinery in the ore dressing tower, 100m to the east, by an endless wire rope.

Burra Heritage Passport

The town of Burra is rich with Cornish mining history and you can unlock the secrets of Burra's Heritage with the unique Passport Key. The Burra Heritage Passport provides first-class access to all these intriguing heritage sites and more!